A reliable, well-balanced benchtop centrifuge is a critical piece of equipment in any busy veterinary diagnostic laboratory. It is pivotal to many veterinary tests, diagnoses and handling procedures while optimising its lifespan and operational safety.

But why is properly balancing your centrifuge before each use so important? How exactly should you go about balancing it?

This guide will walk you through everything you need to know about balancing your veterinary centrifuge for optimal performance, longevity, and safety.

How Does a Balanced Centrifuge Work?

A laboratory centrifuge works by rapidly spinning samples to separate components based on their density. The rotor holds various laboratory samples securely in a fixed position, which, when spun on a vertical spindle, produces strong centrifugal forces – up to several thousand times the force of gravity!

This is known as g-force, which magnifies even tiny differences in weight distribution within the samples and rotor.

Why is It Important to Balance Your Laboratory Centrifuge?

G-forces created by the centrifugation worsen any weight imbalances around the rotor. Even the slightest difference in weight will cause the centrifuge to shake and vibrate uncontrollably, causing undue stress and wear on centrifugal components like motors and bearings. Uneven loads on centrifuge rotors are the most common reason they break down and malfunction.

Over time, this vibrational stress could impact the accuracy of your centrifuge and, in extreme cases, even cause catastrophic failure or explosions. That’s why balancing a high-speed piece of equipment like this is critical.

Follow these simple rules every time you use your centrifuge in your veterinary laboratory or diagnostics:

- Load the rotor symmetrically – distribute weight evenly on both sides

- Always use same-size, equally weighted lab samples opposite each other

- Balance odd samples with matching dummy tubes opposite

- Keep the inside of the centrifuge chamber clean and dry

In essence, by making sure that each centrifuge is balanced with an even and symmetrical load, it will continue to work optimally with minimal chance of malfunctioning.

We’d recommend checking our visual centrifuge balancing PDF guide below for additional instructions.

How To Balance Your Centrifuge

7 Simple Steps for Balancing Your Lab Centrifuge

Whether you’re centrifuging haematocrit tubes, blood sample tubes, Eppendorf tubes, universal containers or commercial diagnostics such as Ovatube tubes, here are seven simple rules to prolong the life, performance, reliability and safety of your veterinary centrifuge.

- Choose the proper rotor for your sample tubes.

Always select a rotor designed specifically for the type and size of consumables you’ll be centrifuging. Using the wrong rotor can increase the chances of accidents or broken tubes.

- Inspect the rotor before loading.

Check that the rotor is in good condition with no cracks or damage and make sure it is securely attached to the drive shaft. Wipe the interior clean and dry before loading samples.

- Organise samples into matching pairs.

Make sure tubes are the same type and filled to equal levels. Pair each one with a matching tube to place on the opposite side of the rotor.

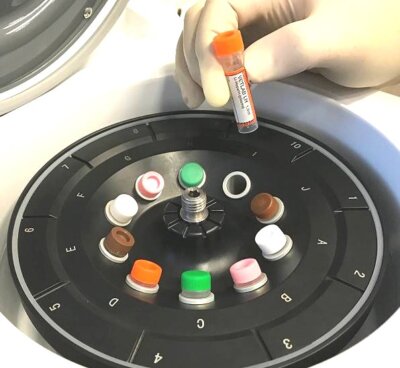

- Load pairs symmetrically into the rotor.

Place each pair directly across from each other, aligned through the central axis. Distribute weight evenly to balance the centrifuge.

- Add balance tubes if needed.

If you end up with an odd unpaired tube, make a matching dummy sample with water to act as a balance. Load this opposite the single tube.

- Secure the lid and check the balance

Close the lid safely and check that the centrifuge is level. Give it a gentle spin by hand to test if it wobbles before starting the cycle.

- Follow safety procedures

Proper balancing of centrifuges only takes a moment and can pay off in a big way. Getting into the habit of checking and balancing regularly will result in safer operation, better performance, and longer equipment lifespan.

Vetlab Supplies provides top centrifuges, tubes, and accessories specially designed for veterinary, clinical, and research applications. Our team is always happy to offer balancing tips and advice to keep your lab running smoothly.

For all your veterinary centrifuge and lab supply needs, contact the experts at Vetlab Supplies on 01798 874567 or visit vetlabsupplies.co.uk.